Product Range

Vacuum Circuit Breakers (Indoor)

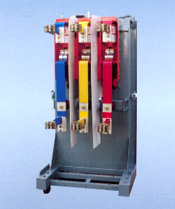

A compact, light weight construction, optimized to give minimum weight to KA ratio.

A unique 'U' shaped insulation barrier housing the Vacuum interrupters, (except for VK 10 Q 40) imparting maximum mechanical strength against electrodynamic forces and provides most effective phase to phase and phase to earth segregation.

A simple motor charged spring operating mechanism noted for its high performance reliability.

A versatile mechanism capable of operating Vacuum Interrupters of any type. Hence, dependence on single source of Vacuum Interrupters eliminated.

Trip free mechanism suitable for repeated auto re closing duty.

Spring charging time of less than 10 seconds. Totally enclosed construction for spring charging motor.

Built-in manual charging handle with every circuit breaker for effortless manual spring charging.

Superior mechanical endurance limit.

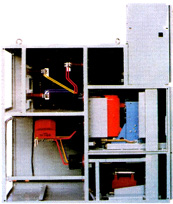

Inside the Cubicle

- Fully segregated circuit breaker compartment ensures that no arc product or foreign body can travel from or to cable and bus bar compartment.

- A screw type racking arrangement for easy insertion and withdrawal of the Circuit Breaker renders perfect contact pressure, independent of operator's force.

- A positive interlock to ensure the circuit breaker insertion to or withdrawal from SERVICE position only when it is OPEN.

Busbars

- Bus bars and jumpers are covered with special heat shrink sleeves which provide effective insulation between phases or phase to earth, even if bridged by vermin or any other conducting body.

- Flexible insulating shrouds cover the bus bar to jumper joints and jumper to stationery contact joints

- Eproxy molded stationary disconnect contacts prvide effective segregation between phases and phase to earth.

A separate segregated compartment for voltage transformers. Voltage transformer connections through epoxy molded contacts.

- Withdraw able voltage transformer truck arrangement.

- Automatic safety shutters cover the live parts when voltage transformer is withdrawn outside the crucible.

- Adequate space for entry and termination of two sets of 3-core or 6 nos. (2 per phase of single core) cable connections.

- Additional sets of cables or current transformers can be housed within modular rear extension.

| Interrupting Current (Voltage) |

25 (KA) |

31.5 (KA) |

40 (KA) |

| 7.2 KV |

|

|

|

| 12 KV |

|

|

|

| 24 KV |

|

|

|

| 36 KV |

|

|

|

Draw out Unit

| Rated Current / Voltage |

630 (A) |

1250 (A) |

2000 (A) |

2500 / 3150 (A) |

| Upto 12 KV |

|

|

|

|

Vacuum Circuit Breakers - (Outdoor)

| Interrupting Current (Voltage) |

25 (KA) |

| 12 KV (630/1250 A) |

|

| 36 KV (1250/1600 A) |

|

|

|

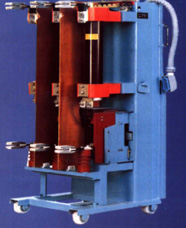

Vacuum Contactor-(Indoor) (Product features)

- A compact , light weight construction, optimized to give minimum weight.

- Excellent Choice for switching motors transformers and Capacitors.

- Available In two versions Electrical and Mechanicals.

- Exceptionally High mechanical and electrical life( In million operations)

- Low Chopping Current ( maximum 1.5 Amp and Avg 0.9 Amp)

- Suitable for High Switching frequency ( around 300 operations per hour)

- Cheaper / cost saving device for motor , transformer and capacitor switching.

- Suitable for 3.3kv / 6.6kV 400 Amp.

| Current (Voltage) |

3.6 (KV) |

7.2 (KV) |

12 (KV) |

| Rated Current – Amp |

400 |

400 |

400 |

| Interrupting Capacity-KA |

8.0 |

8.0 |

8.0 |

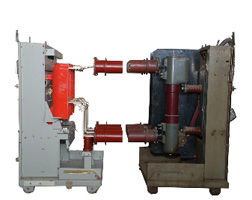

Retrofit (Indoor MOCB Panel) (Product features)

|

|

|

| Fig1 : 'Jyoti' MOCB Truck |

|

Fig2 : 'Jyoti' Cassette type VCB Draw-out unit |

| |

|

| Without PT |

|

With PT |

| |

Retrofitting Medium Voltage Old MOCB Switchgear with VCB

- Jyoti MOCB Panel

- Other make MOCB Panel

|

|

|

| Fig 3 : Rear View of 'Jyoti' One-to-One VCB |

|

Fig 4 : Front View of 'Jyoti' One-to-One VCB |

Jyoti Ltd. has successfully carried out 'Retrofitting' of nearly 1000 MOCBs with VCBs in last decade at number of installations.

- Upgrading Technology

- Mocbs Vis-A-Vis Vcbs - Advantages

- One-To-One Replacement

- Casette-Type Draw-Out Unit

Jyoti MOCB Panels

Other Make MOCB Panels

(Jyoti can undertake Retrofit of VCB's in MOCB panels of other make. Jyoti has successfully retrofitted VCBs in 11KV BHEL MOCB panels for 630, 1250 and 2500 Amp.)

| |

Existing Panel |

Existing MOCB |

Recommended VCB |

| Sr.No |

Type of MOCB Panel |

Type of MOCB |

Current Rating A |

Fault Level KA |

Type of MOCB |

Current Rating in Amp |

Fault Level KA |

| 1 |

11/6.6/3.KV 860/PA1 |

OZ2

OZ2

OZ2 |

630

1250

800 |

13.2

13.2

18.4 |

VK10J25 VK10M25 VK10M25 |

630

1250

1250 |

25

25

25 |

| 2 |

11/6.6/3.KV ZK4/PB2 |

OZ2 |

630

1250 |

18.4

18.4 |

VK10J25 VK10M25 |

630

1250 |

25

25 |

| |

-do- |

OD1 |

630

1250

1600 |

25

25

25 |

VK10J25 VK10M25 VK10P25 |

630

1250

2000 |

25

25

25 |

| 3 |

11/6.6/3.3KV PA3/PA3-1 |

OZ2 MT1 |

630

1250

800 |

13.2

18.4

18.4 |

VK10J25 VK10M25 VK10M25 |

630

1250

1250 |

25

25

25 |

| 4 |

11/6.6/3.3KV PB3/PB3-M |

MS1/MS2 MS3 |

1250

1250

1250 |

25

40

25 |

VK10M25 VK10M40 VK10M25 |

1250

1250

1250 |

25

40

25 |

| 5 |

11/6.6/3.3KV PA-3/M |

MT-1 MS-3 |

630/1250 1250/1600 |

25

40 |

VK10J25 VK10M25 VK10M40 VK10P40 |

630/1250 1250/2000 |

25

40 |

Jyoti Ring Main Unit

Jyoti Ltd has developed a SF6 gas insulated Ring Main Unit with a trade mark of "Jyoti Ring TM ". Jyoti Ring has developed with the technical collaboration from one of the UK based company. This product has not only developed successfully but also Type tested in one of the most reputed European Laboratory. The total International certification has done as per IEC 62271-100/200/103/102.

Design of the Jyoti Ring is a modular & any combination is possible as per customer's requirement. There are three basic modules

- Load Break Switch (Type –L) – 15.5kV, 21kA, 630A

- Vacuum Circuit Breaker (Type – V) - 15.5kV, 21kA, 630A

- Direct Link (Type - D) - 15.5kV, 21kA, 630A

The Type tested ratings of the Jyoti Ring are as follow

| Rated Voltage |

15.5kV |

| Power Frequency Withstand voltage |

38/45kV |

| Impulse Withstand Voltage |

75/85kV |

| Rated Frequency |

50Hz |

| Operating temperature range |

-5°C to +55°C |

| Rated continuous current |

630A |

| Rated Short-time withstand Current |

21kA rms, 3sec |

| Rated peak withstand current |

52.5kA |

| Rated symmetrical interrupting current for VCB |

21kA |

| Rated asymmetrical making current |

52.5kA |

| Rated operating sequence of Circuit Breaker |

O-3min-CO-3min-CO |

| Rated cable charging interrupting current |

25A |

| Mechanical operating sequence CB(C-O) M2 |

10000 |

| Mechanical operating sequence LBS(C-O) M2 |

5000 |

| Minimum operating Gas Pressure |

0.3 bar G |

The developed combinations are as follow

| SINGLE WAY |

| Sr.No. |

Part No. |

Description |

Type |

| 1 |

05.611.001.00 |

LINE SWITCH UNIT COMPLETE ASSEMBLY |

L |

| 2 |

05.611.003.00 |

CIRCUIT REAKER UNIT COMPLETE ASSEMBLY |

V |

| 3 |

05.611.004.00 |

LS UNIT COMPLETE ASSEMBLY WITH REMOTE OP |

L |

| 4 |

05.611.006.00 |

CB COMPLETE ASSEMBLY WITH REMOTE OP |

V |

| 2 WAY WITH LINK |

| 1 |

05.641.001.00 |

DIRECT LINK CIRCUIT BREAKER UNIT ASSEMBLY-RH EXT. |

DV |

| 2 |

05.641.002.00 |

DIRECT LINK CIRCUIT BREAKER UNIT ASSEMBLY REMOTE OP. |

DV |

| 3 |

05.641.003.00 |

DIRECT LINK 3 IN 1 - DVV ASSEMBLY |

DVV |

| 3 WAY RMU |

| 1 |

05.601.002.00 |

CB COMPLETE 3 IN 1 - LLVE ASSEMBLY |

LLVE |

| 2 |

05.601.004.00 |

CB COMPLETE 3 IN 1 - LLV ASSEMBLY |

LLV |

| 3 |

05.601.006.00 |

CB COMPLETE ASSLY WITH REMOTE OP-LLVE |

LLVE |

| 4 |

05.601.008.00 |

CB COMPLETE ASSLY WITH REMOTE OP-LLV |

LLV |

| 5 |

05.601.002.01 |

LBS COMPLETE 3 IN 1 - LLLE ASSEMBLY |

LLLE |

| 6 |

05.601.004.01 |

LBS COMPLETE 3 IN 1 - LLL ASSEMBLY |

LLL |

| 7 |

05.601.006.01 |

LBS COMPLETE ASSLY WITH REMOTE OP-LLLE |

LLLE |

| 8 |

05.601.008.01 |

LBS COMPLETE ASSLY WITH REMOTE OP-LLL |

LLL |

| 9 |

05.601.002.02 |

CB COMPLETE 3 IN 1 - LVVE ASSEMBLY |

LVVE |

| 10 |

05.601.004.02 |

CB COMPLETE 3 IN 1 - LVV ASSEMBLY |

LVV |

| 11 |

05.601.006.02 |

CB COMPLETE ASSLY WITH REMOTE OP-LVVE |

LVVE |

| 12 |

05.601.008.02 |

CB COMPLETE ASSLY WITH REMOTE OP-LVV |

LVV |

| 13 |

05.601.002.03 |

CB COMPLETE 3 IN 1 - VVVE ASSEMBLY |

VVVE |

| 14 |

05.601.004.03 |

CB COMPLETE 3 IN 1 - VVV ASSEMBLY |

VVV |

| 15 |

05.601.006.03 |

CB COMPLETE ASSLY WITH REMOTE OP-VVVE |

VVVE |

| 16 |

05.601.008.03 |

CB COMPLETE ASSLY WITH REMOTE OP-VVV |

VVV |

| 4 WAY RMU |

| 1 |

05.631.001.00 |

CB COMPLETE 4 IN 1 - VLLVE ASSEMBLY |

VLLVE |

| 2 |

05.631.002.00 |

CB COMPLETE 4 IN 1 - VLLV ASSEMBLY |

VLLV |

| 3 |

05.631.003.00 |

CB COMPLETE ASSLY WITH REMOTE OP-VLLVE |

VLLVE |

| 4 |

05.631.004.00 |

CB COMPLETE ASSLY WITH REMOTE OP-LLV |

VLLV |

| 5 |

05.631.001.01 |

CB COMPLETE 4 IN 1 - LVVVE ASSEMBLY |

LVVVE |

| 6 |

05.631.002.01 |

CB COMPLETE 4 IN 1 - LVVV ASSEMBLY |

LVVV |

| 7 |

05.631.003.01 |

CB COMPLETE ASSLY WITH REMOTE OP-LVVVE |

LVVVE |

| 8 |

05.631.004.01 |

CB COMPLETE ASSLY WITH REMOTE OP-LVVV |

LVVV |

| 9 |

05.631.001.02 |

CB COMPLETE 4 IN 1 - LLLVE ASSEMBLY |

LLLVE |

| 10 |

05.631.002.02 |

CB COMPLETE 4 IN 1 - LLLV ASSEMBLY |

LLLV |

| 11 |

05.631.003.02 |

CB COMPLETE ASSLY WITH REMOTE OP-LLLVE |

LLLVE |

| 12 |

05.631.004.02 |

CB COMPLETE ASSLY WITH REMOTE OP-LLLV |

LLLV |

| 13 |

05.631.001.03 |

CB COMPLETE 4 IN 1 - LLLLE ASSEMBLY |

LLLLE |

| 14 |

05.631.002.03 |

CB COMPLETE 4 IN 1 - LLLL ASSEMBLY |

LLLL |

| 15 |

05.631.003.03 |

CB COMPLETE ASSLY WITH REMOTE OP-LLLLE |

LLLLE |

| 16 |

05.631.004.03 |

CB COMPLETE ASSLY WITH REMOTE OP-LLLL |

LLLL |

| 17 |

05.631.001.04 |

CB COMPLETE 4 IN 1 - VVVVE ASSEMBLY |

VVVVE |

| 18 |

05.631.002.04 |

CB COMPLETE 4 IN 1 - VVVV ASSEMBLY |

VVVV |

| 19 |

05.631.003.04 |

CB COMPLETE ASSLY WITH REMOTE OP-VVVVE |

VVVVE |

| 20 |

05.631.004.04 |

CB COMPLETE ASSLY WITH REMOTE OP-VVVV |

VVVV |

Retrofit Solutions From Jyoti

In the 1950s to 1990 MOCBs were the mainstay of switching devices for medium power generation and distribution networks. Jyoti was first to introduce the concept of replacing old MOCBs with latest VCB technology thereby increasing the service life of the existing switchgear panels. Retrofit solutions for their MOCBs as well for other make MOCBs.

This year Jyoti has successfully designed, developed and commissioned retrofit solution for NGEF 12kV, 1250 Amp 25kA MOCB type EKU 5012 at a public sector refinery in western India. The retrofit solution has been completed one month ahead of schedule with successful commission and taking on load of 19 numbers vacuum breakers on 17th May 2010.

As of now Jyoti has more than 2000 retrofit breaker in service.

|

|

|

| EKU 5012 Retrofit |

Exact Match |

VCB Inside Panel |

|

|

| Our Team |

Retrofit Vcbs Ready For Insertion In Panels |